Aestrik Techno, Mumbai, is a leading importer, exporter, and supplier of various digital printers, printers, plotters, engravers, and routers in India. They offer Fiber laser metal cutting large printing width and high productivity digital printers, and provide after-sales support. Their goal is to accelerate productivity and increase return on investment.

Fiber Laser Metal Cutting Machines are revolutionizing automotive manufacturing by enhancing precision and efficiency. These cutting-edge technologies are reshaping the industry, reducing waste and errors. This blog post explores the fundamental role, real-world applications, and future of these machines in the automotive manufacturing sector, aiming to create a world where every component is crafted with unparalleled precision. Fiber Laser Metal Cutting Machines are crucial in automotive manufacturing for precision and efficiency, ensuring each vehicle meets high standards in quality and production speed. Fiber Laser Metal Cutting Machines are crucial in modern automotive production, shaping raw materials like chassis components and sheet metal with precision. They are versatile, adaptable, and work with various materials like steel, aluminum, and alloys. Despite not being as popular as autonomous vehicles or electric powertrains, their precision reduces errors, costs, and production times, making vehicles more affordable for consumers.

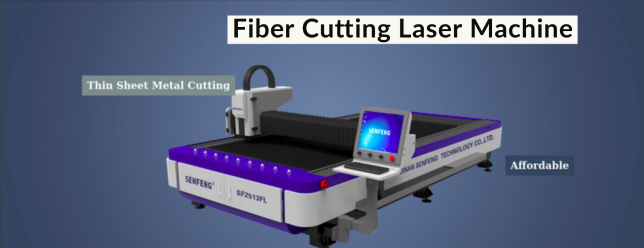

Fiber Laser Metal Cutting Machines are revolutionizing various aspects of automotive manufacturing.

The precision has been enhanced

Fiber laser cutting machines offer unparalleled precision, allowing automotive manufacturers to produce parts with incredibly tight tolerances. This precision ensures that components fit together seamlessly, leading to safer and more reliable vehicles.

The efficiency has been significantly enhanced

These machines significantly reduce production time by virtue of their high cutting speeds. Shorter production cycles enable manufacturers to meet demand promptly, respond to market changes swiftly, and ultimately reduce costs associated with extended manufacturing processes.

The intricate shapes and designs that can be found in various forms

The ability of fiber laser machines to cut complex shapes and designs allows automotive designers to push the boundaries of creativity. This leads to innovative vehicle designs that can capture consumers’ attention and drive sales.

Customization and Personalization

With fiber laser technology, automotive manufacturers can easily accommodate customization requests, from unique paint job designs to personalized interior features. This ability to cater to individual customer preferences can enhance brand loyalty and increase sales.

The Fiber Laser Metal Cutting Machines have various applications in various industries.

Fiber laser metal cutting machines are essential in various industries, including automotive, aerospace, sheet metal fabrication, electronics, medical device production, jewelry and fashion accessories, architectural metalwork, tool and die making, prototyping, art and sculpture, renewable energy, shipbuilding, consumer goods production, defense and military applications, and metal recycling. They are used to cut and shape metal components for vehicle frames, chassis, body panels, exhaust systems, aircraft, and spacecraft, and to create intricate parts for devices like smartphones, laptops, and printed circuit boards. In the medical industry, they are used for surgical instruments, implants, and medical device components, while in jewelry and fashion accessories, they create intricate metal artwork and installations. Fiber laser technology also plays a role in metal recycling, contributing to environmental sustainability.

Aestrik Techno, Mumbai, is a leading importer, exporter, and supplier of various digital printers, printers, plotters, engravers, and routers in India, offering high-quality products and after-sales support to its clients.Fiber Laser Metal Cutting Machines have revolutionized the automotive manufacturing industry by achieving precision and efficiency. These machines have transformed production processes, making them leaner, greener, and more cost-effective. They also provide cost savings and competitiveness, making high-quality vehicles more accessible to consumers. Additionally, Fiber Laser technology has expanded the realm of design possibilities, enabling intricate detailing and customization. These machines are not just tools; they are the driving force behind the automotive industry’s evolution. Emerging trends and continuous advancements promise a future where precision, efficiency, sustainability, and cutting-edge design will continue to define the vehicles we drive. As we navigate this exciting future, Fiber Laser technology is here to stay, propelling automotive manufacturing to new heights of excellence.